We pride ourselves on being a leading force in the Natural Rubber and Downstream Oil & Gas industries. Our operations are grounded in quality, reliability, and global trust, reflecting the solid relationships we have cultivated with partners worldwide.

We lead the way with the production of crumb rubber, focusing on the premium TSR 10 and TSR 20 grades. Whether it’s for tire manufacturing or industrial applications, our rubber stands as a hallmark of innovation and reliability.

| Product: NSR 10 | Product: IHL/TSR 10 | ||||

|---|---|---|---|---|---|

| Description | Measure | Value | Description | Measure | Value |

| Dirt Retained on 45mm Aperture | Max % Weight | 0.1 | Dirt Retained on 45mm Aperture | Max % Weight | 0.08 |

| Ash Content | Max % Weight | 0.75 | Ash Content | Max % Weight | 0.75 |

| Volatile Matter | Max % Weight | 1.0 | Volatile Matter | Max % Weight | 0.8 |

| Wallace Rapid Plasticity | Po | 30 | Wallace Rapid Plasticity | Po | 32 |

| Plasticity Retention Index | PRI (Min %) | 50 | Plasticity Retention Index | PRI (Min %) | 55 |

| Nitrogen Content (Testing Device not available) | Max % Weight | NIL | Nitrogen Content (Testing Device not available) | Max % Weight | NIL |

| Mooney Viscosity | Min % Weight | 60 | Mooney Viscosity | Min % Weight | 60 |

| Product: NSR 20 | Product: IHL/TSR 20 | ||||

|---|---|---|---|---|---|

| Description | Measure | Value | Description | Measure | Value |

| Dirt Retained on 45mm Aperture | Max % Weight | 0.2 | Dirt Retained on 45mm Aperture | Max % Weight | 0.16 |

| Ash Content | Max % Weight | 1.0 | Ash Content | Max % Weight | 1.0 |

| Volatile Matter | Max % Weight | 1.0 | Volatile Matter | Max % Weight | 0.8 |

| Wallace Rapid Plasticity | Po | 30 | Wallace Rapid Plasticity | Po | 30 |

| Plasticity Retention Index | PRI (Min %) | 50 | Plasticity Retention Index | PRI (Min %) | 50 |

| Nitrogen Content (Testing Device not available) | Max % Weight | NIL | Nitrogen Content (Testing Device not available) | Max % Weight | NIL |

| Mooney Viscosity | Min % Weight | 60 | Mooney Viscosity | Min % Weight | 60 |

We derive our rubber from latex, a sticky, milky white substance that is extracted from rubber trees through a meticulous process called rubber tapping.

Using precision techniques, we carefully slit the bark of the trees in a spiral pattern with a tapping knife, allowing the latex to flow efficiently into collection cups.

Once collected, the latex is left to coagulate, after which we gather the rubber lumps.

This harvesting process is carried out daily to ensure a consistent and high-quality supply for our clients.

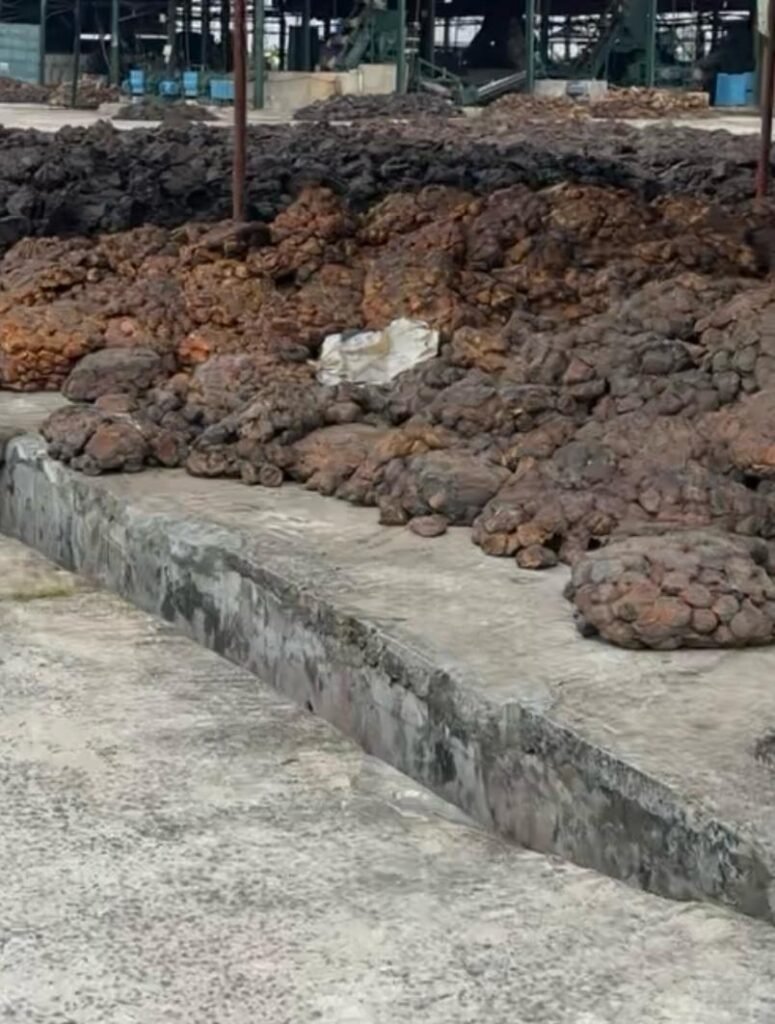

The harvested dry rubber lumps from our trees are carefully gathered and placed into rubber pits, where they undergo a secondary coagulation process.

Once the pits are filled, we add coagulants to initiate the transformation. The process is complete when the smaller lumps bond together to form larger ones.

These newly formed rubber lumps are then weighed and transported to our factory for further processing, ensuring the highest quality for our clients.

Before we achieve the final product, crumb rubber, the rubber lumps go through several processing stages.

First, the lumps are thoroughly washed to eliminate any dirt or particles, then crushed, flattened, and shredded to prepare them for the final processing in high-temperature ovens.

Once oven-baked, the crumb rubber is carefully removed from the baking pans and weighed to ensure it meets the standard weight of 35kg per bale. The bales are then packed and stored.

Crumb rubber, as a semi-finished product, is widely used in the production of tires (for automobiles and aircraft), airbags, rubber gloves (both medical and commercial), plastics, shoes, flooring (including gym and kitchen), erasers, adhesives, coatings, PPE, and more.

At Abel Bellvic J Limited, we take pride in supplying top-tier downstream products that keep your communities moving. From our state-of-the-art filling stations to our expertly handled distribution network, we ensure that every drop of fuel meets the highest standards of quality.